Stainless steel square bars are known to have great strength, durability, and resistance to corrosion, making them important in various industries. Such Bars are used in construction, automotive, and infrastructure industries. In India, the industrial sectors are rapidly growing, and so are the export opportunities. This is why there is an increasing demand for SS square bars, especially on grades 304 and 316.

This guide is for anyone looking for the best manufacturers in India. I have listed a few companies I know that deal with high-quality stainless steel grade square bars and have an excellent reputation for precision and supply across the country.

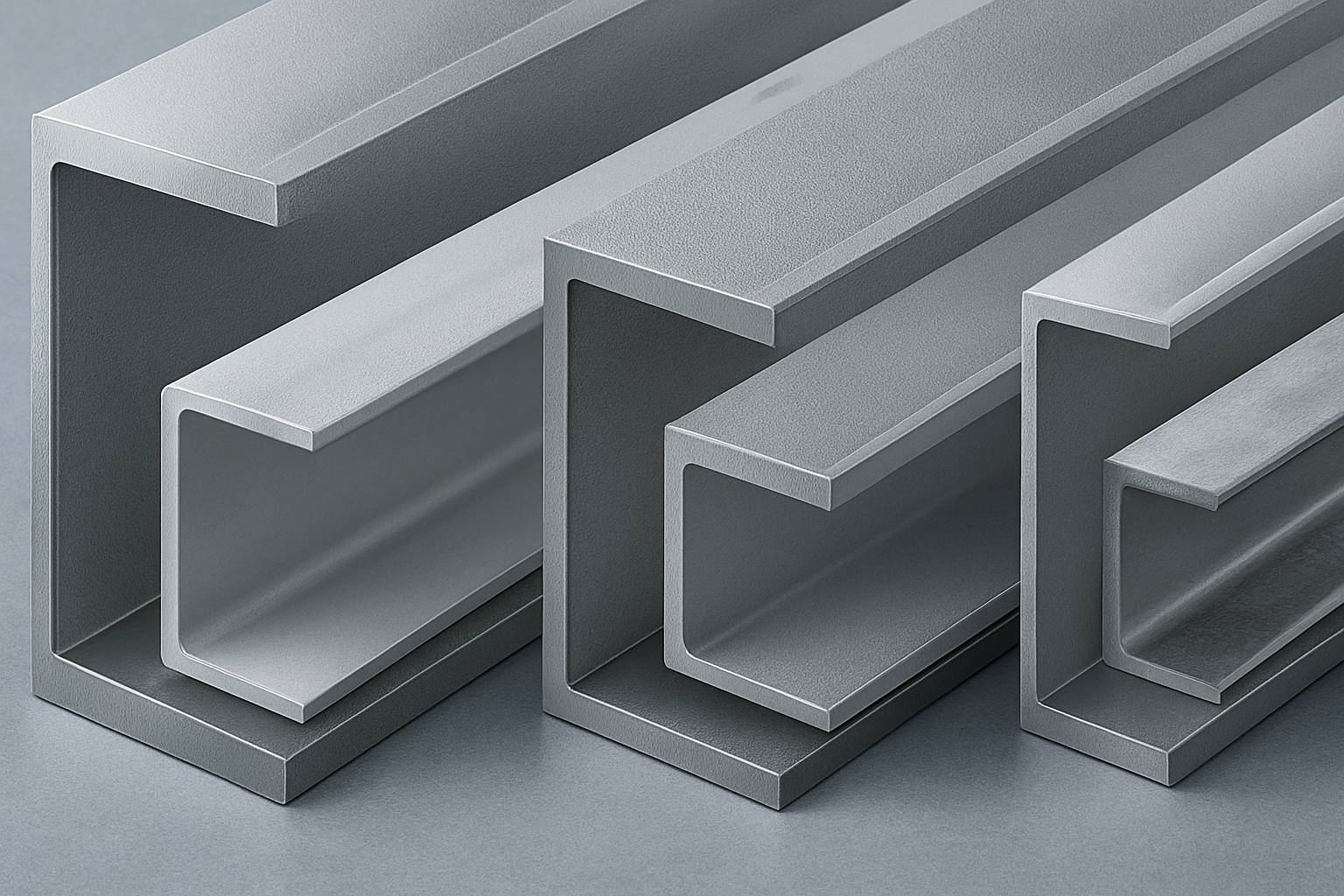

Why Select Stainless Steel Square Bars?

These offer stainless steel square bars:

- Resistant to rust or corrosion in difficult conditions

- Achievable aesthetic appearance for architectural applications

- Severe enduring strength compared to its weight

- Exceptional ease in welding and shaping

Due to these characteristics, they can be used in constructions like stair railings, machinery, and even decorations.

The Importance of Stainless Steel Square Bars in Different Industries

Because of their structural integrity, ability to withstand deterioration, and their multifunctional application, stainless steel square bars are pivotal in different industries. For instance, in construction and even decorative works, stainless steel grades 316 and 304 are highly preferred. The same applies to some fabrication and infrastructure machinery work, too.

Stainless Steel Square Bars of Superior Quality: Important Characteristics

Indian industry leaders supply square bars in stainless steel with the following characteristics:

- Adjustment in alignment and geometry processing results in the minimization of surface finish processing.

- Mechanical properties with greater efficiency, including tensile strength and toughness, are noteworthy.

- This describes protection from corrosion for both external and internal application settings.

- Adds customization in terms of expansion and reduction to different sizes and lengths available.

Reliability, consistency, and protective function in performance, alongside visual appeal, are fundamental in specific industries for these features.

Stainless Steel Square Bars and Their Advantages

- Protection Against Corrosion: Perfect for internal and external use, particularly in coastal and chemically active regions.

- Strength and Durability: Useful in heavy-load frameworks and the working mechanical components of machines.

- Reduced Maintenance: Stainless steel square bars have minimal upkeep once set up, which is cost-efficient over time.

- Environmentally Friendly: Use in modern engineering and architecture makes recycled stainless steel a sustainable choice without compromising structural integrity.

- Various Dimensions and Grades Offered: These are offered in different lengths, thicknesses, and finishes to suit industrial requirements.

How to Choose the Right Manufacturer

As you shortlist manufacturers for stainless steel square bars, the following criteria will be helpful:

- Industry certifications, such as ISO 9001, ensure recognized standards of quality.

- Available production capacity that should be able to meet your schedule.

- Comprehensive selection of grades and sizes to avoid settling on unsuitable materials.

- Reputation of the manufacturer and client feedback.

- Technical support after delivery for clarifications or concerns.

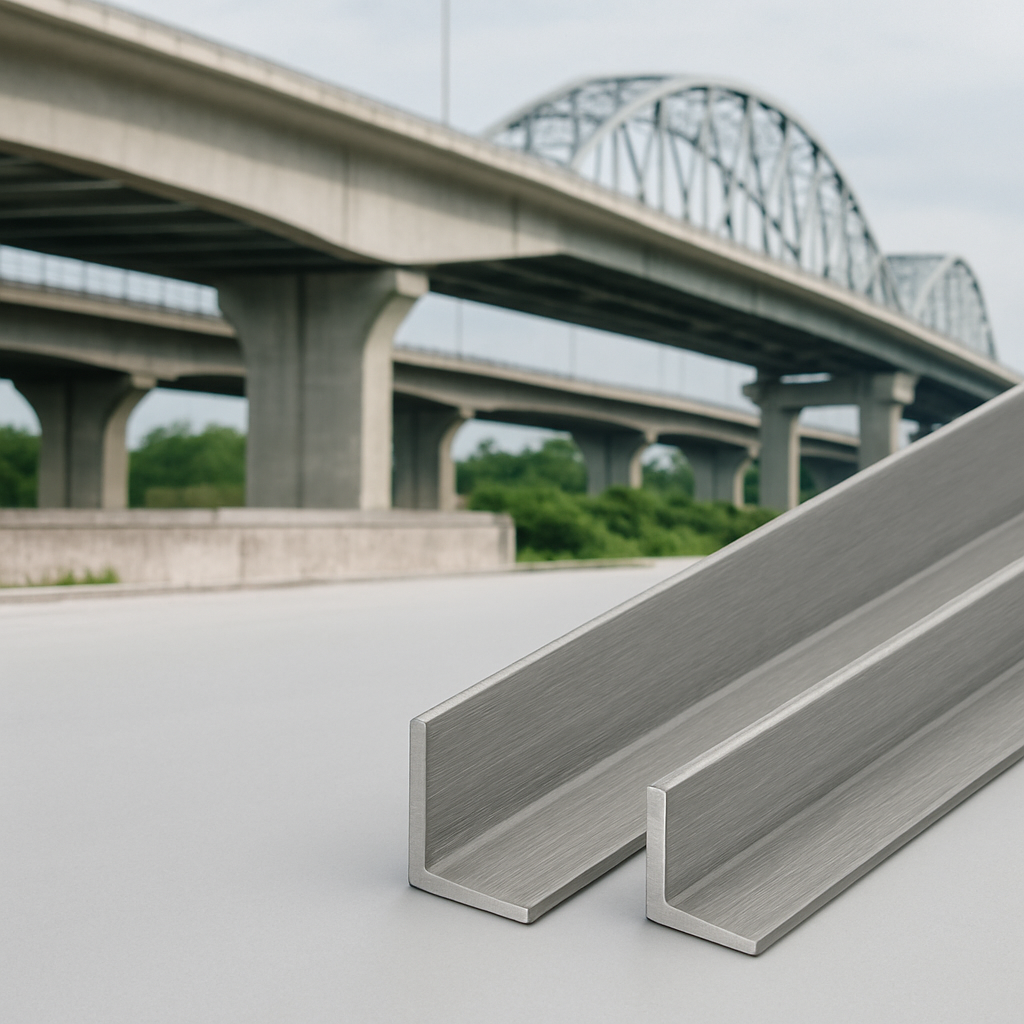

Also Read: Top Stainless Steel Angle Manufacturer in India: Quality You Can Trust

Conclusion

The role of square stainless steel bars has evolved from being a mere raw material to a crucial component of modern-day engineering, architecture, and industrial workflows because of their incredible strength and reliability. Their unparalleled resilience, corrosion resistance, and versatility instate them as materials of choice across various industries in India and the globe.

Selecting the appropriate grade of SS square bars and employing them in commercial construction, heavy fabrication, or industrial design can greatly improve the performance and durability of structures.