Close

Our state-of-the-art manufacturing facilities, equipped with advanced European technology, are supported by a highly skilled and experienced team of development, production, and quality engineers. Guided by the philosophy of being ‘A Step Ahead,’ our team swiftly adapts to evolving market demands, delivering tailored solutions to meet customer needs in the shortest possible time. Additionally, we ensure our products consistently meet the stringent specifications required by our global clientele.

Our melting furnace is at the heart of our production process, designed to deliver exceptional quality and efficiency.

Our 16″ Rolling Mill is a key part of our production line, designed for high-efficiency stainless steel rolling.

Key Features:

Our 10″ Rolling Mill combines semi-automatic controls with precision, designed for efficient production of high-quality stainless steel long products.

Key Features:

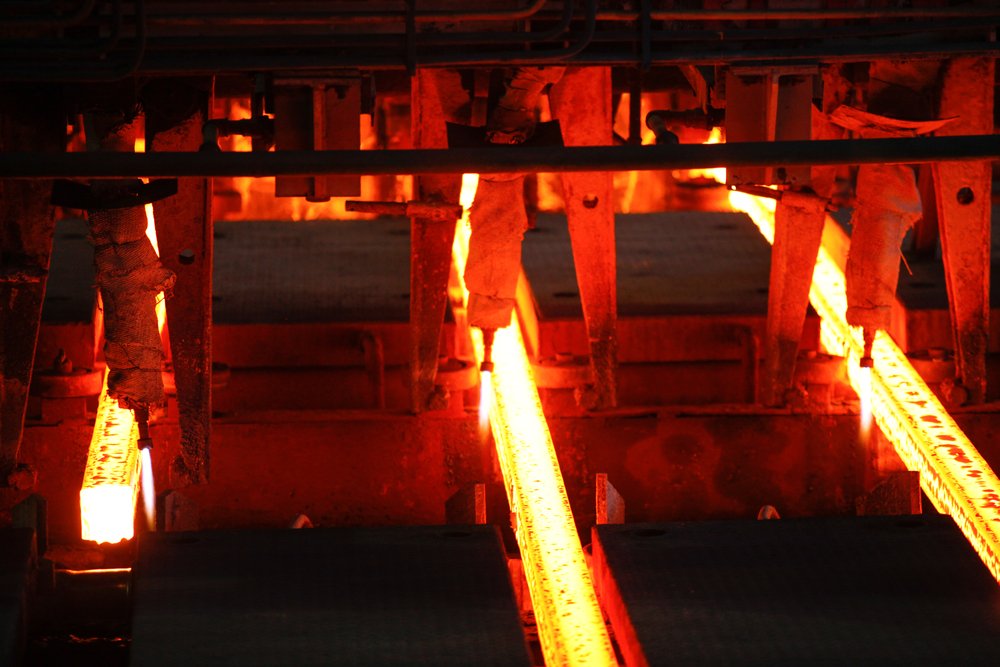

Our Billet Caster is a modern, technologically advanced system designed for the efficient casting of billets, ensuring high precision and quality in every cast.

Key Features:

Our Solution Annealing Furnace is designed for heat treatment of stainless steel, ensuring optimal strength and durability for round, hex, and square products.

Key Features:

Our Wire Rod Drawing Schumeg Machine is designed for precise and efficient drawing of wire rods, ensuring high-quality and accurate wire products.

Key Features:

Our Shot Blasting Machine is designed to provide efficient surface cleaning and finishing for stainless steel products.

Key Features:

Our Pickling Plant is designed for the chemical treatment of stainless steel, ensuring excellent surface quality and corrosion resistance.

Key Features: