In terms of structural integrity, ease of maintenance, and operational functionality, stainless steel channels, as a material, offer a wide range of applications across various industries. If you are involved in construction, fabrication, manufacturing, or infrastructure, these channels, such as SS304U and SS316L, offer unrivaled utility.

In this guide, you will discover the differences between these channels, their uses, advantages, and how choosing a trusted stainless steel channel manufacturer in India can make or break your project.

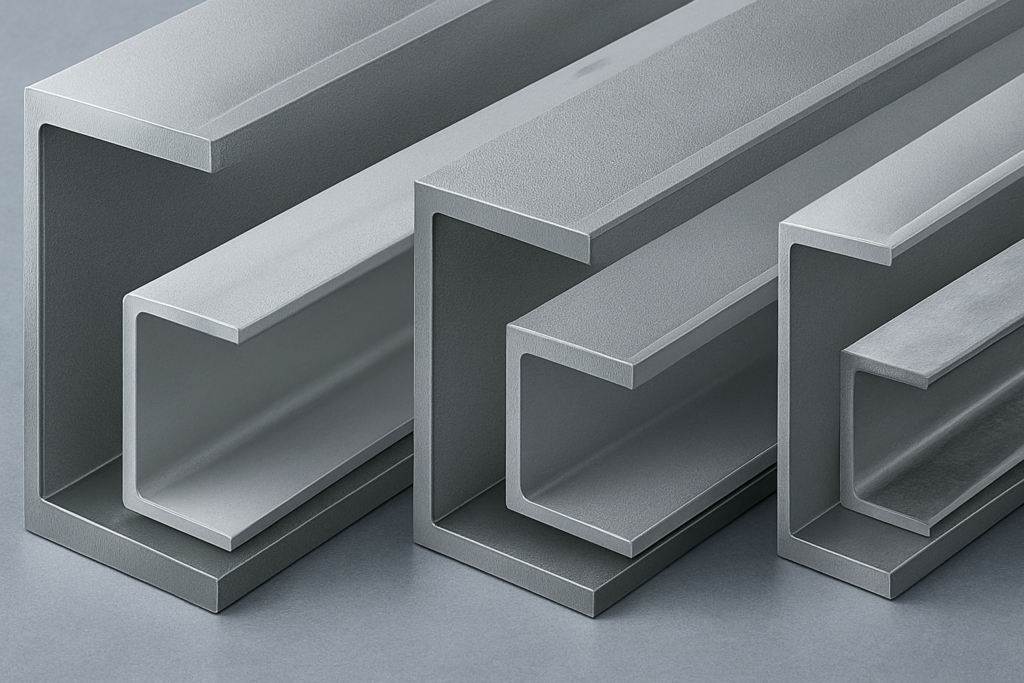

What are Stainless Steel Channels?

Like other types of stainless steel shapes, channels are long, uniform U or C stainless steel shape bars used as load-bearing supports in: Beams, frameworks and other architectural components. The corrosive resistant, strong, and aesthetically pleasing materials are sought after in:

- Industrial frameworks

- Infrastructure projects

- Equipment support

- Transportation and shipping containers

- Decorative structures

Different grades and shapes are used based on the desired outcome. Two of the most popular ones are:

- SS 304 U Channel

- SS 316 C Channel

SS 304 U Channel – Popular, Practical, and Multifunctional

SS 304 is the most common type of stainless steel used around the world because of its affordable price, formability, and stainless steel’s good resistance to corrosion. It has a composition of chromium (18%) and nickel (8%), which is sufficient for most applications.

304 U Channel SS Stainless Steel Highlights

- Ability to withstand corrosion from exposed chemicals and atmospheres.

- High formability and strength.

- Indoor and outdoor suitability for mild climates.

- Economically advantageous for projects on a larger scale.

Food processing and packaging units:

- Furniture and fixtures for interior railings and trims.

- Support structure for factories and low to mild exposure to chemicals.

SS 316 C Channel – Industry Leader in High Corrosive and Stressful Areas

SS 316 is a more advanced steel than the others since it contains molybdenum, which increases resistance to chloride and other harsh chemicals. It has a shape channel which is beneficial in marine, pharmaceutical, and other highly corrosive parts of the world.

Key Features of SS 316 C Channel

- Good resistance to saline and acidic environments.

- Endure high temperatures.

- Industrial, marine, and medical grade applications.

Food and beverage processing and packaging equipment.

- Construction and civil infrastructure in coastal areas.

- Chemical and pharmaceutical plants and laboratories.

- Marine docks, shipbuilding, and ship servicing.

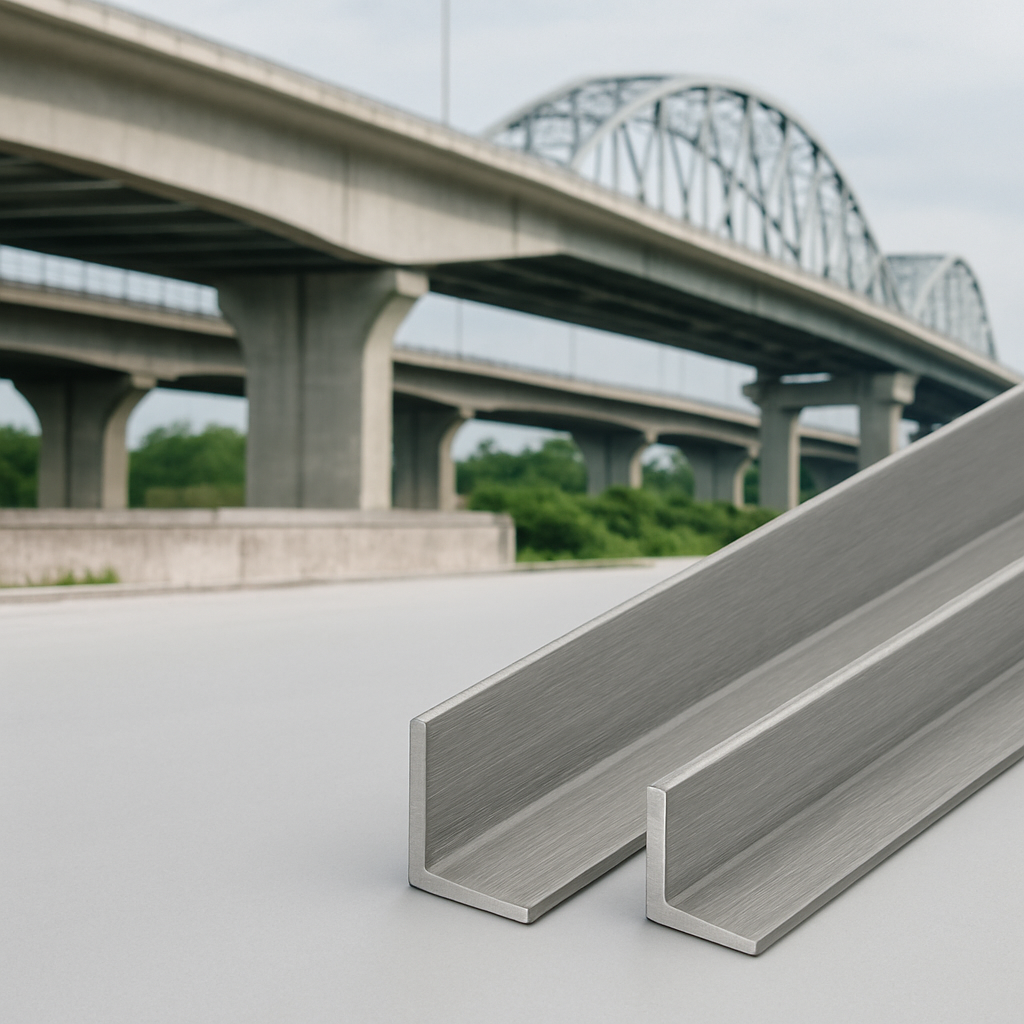

Infrastructure Incorporation of Stainless Steel Channels

The importance of Stainless steel channels in modern construction extends to their unique characteristics. Their application in the skeletal structure of buildings as well as in civil construction underscores their versatility.

- Commercial Construction: The malls along with service and ticketing offices as well as the airports have partitioning and framing ceilings as well as dividers constructed from ss 304 u channels.

- Marine & Coastal Use: These channels are extensively used for construction in docks such as ss 316 c channels for jetties and offshore constructions because of their salt and corrosion capability.

- Industrial Applications: The food and chemical industries utilize Stainless steel for their frames and conveyor systems because of the durability standard stainless steel offers.

- Infrastructure Projects: Construction of bridges, flyovers, and metro systems require the use of stainless steel for its load bearing capacities as well as low maintenance.

- Interior Design: The elegant look of ss 304 channels make them ideal for accentuating modern trims and stair rails.

Why Is It Important to Choose an Indian Stainless Steel Channel Manufacturer with a Good Reputation?

Product quality and consistency are equally important as sourcing grade when investing in stainless steel infrastructure. Leading Indian manufacturers meet world-class standards, offer tailored dimensions, and provide mill test certificates with every shipment.

Look for producers who provide:

- An extensive range of stainless steel grades and profiles

- CNC and precision cutting

- Delivery across India in a timely manner

- Professional guidance in the channel’s application and use

Also Read: Stainless Steel Angles SS 304 and 202: Key Differences, Benefits & Best Use Cases

Final thoughts

The channels SS 304 U and SS 316 C are both advantageous and advantageous depending on the project’s needs. By choosing a well-known stainless steel channel manufacturer in India, you are assured timely delivery, top-notch quality, and technical support, which strengthens your infrastructure needs.